How To Implement Feedback Loops in Your Kanban System

The Kanban basics are rooted in six principles: visualizing work, limiting works in progress, focusing on flow, making processes clear, improving continuously, and implementing feedback loops. All of these principles, when implemented successfully, will make success a possibility for any organization. To make all of these possible, communication is

What is Lean Agile Project Management?

Much is demanded of businesses in this modern world. Competition is tough. Consumer standards are high. And the market has never been as technology-driven as before. For businesses that want to thrive, they know that having a good product alone is insufficient. They need to look into how they

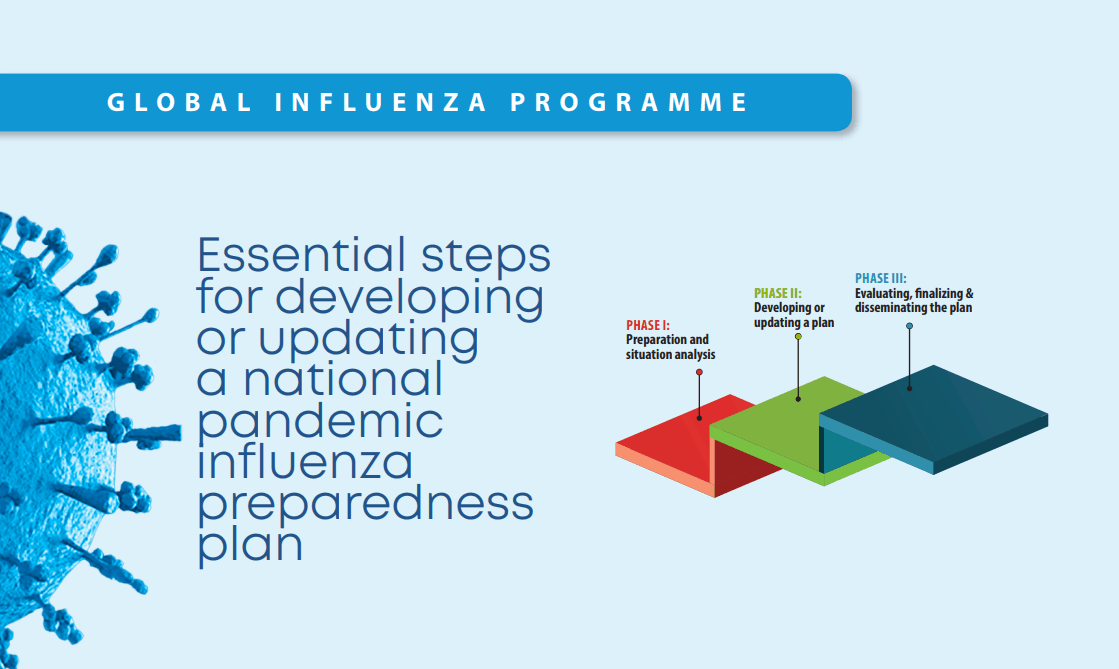

COVID-19 Pandemic Preparedness Plan in Kanban – World Health Organization

As this world pandemic hit our global community, we wanted to find a way to provide help. In times like this, it’s key to understand your specific strengths and focus on these to help others. In our case, we provide the ability to create online Kanban boards and

Why Your Kanban System Implementation Failed: Having a Kanban Board is NOT Enough

Kanban system implementation may seem easy. Some think that having a board with a bunch of cards is what all Kanban is about. But it’s much more than the columns, swimlanes, and cards that flow through a board. Making a successful kanban system implementation is another story. Kanban is a

Using Kanban to Keep Your Kids Focused While They are Required to Attend Classes Online

How does a Kanban Coach keep their kids focused when they are required to attend online classes? The Answer is: You build a Kanban board of course!! Online classes you say, no problem I say. And so a Kanban board was built. Using the power of Kanban, I immediately

5 Kanban Board Examples for Manufacturing

If you’re not new to Kanban, you know how it originated from the automotive manufacturing industry in Japan. From its roots in the manufacturing industry, we know today has since evolved into full-blown process management and improvement technique. It’s no longer just used to manage parts and stock levels