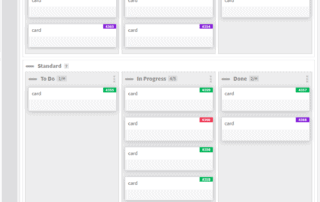

Kanban Classes of Service

When it comes to knowledge work, the type of items that teams get to work on varies in urgency, requirements, perceived business value and level of priority. For example, a software development team has just gone live with their application. The team is now expected to work on both enhancements and maintenance work. At the start of the workday, they are scheduled to work on features for a planned release version and a few minor production issues. Midday comes and a security vulnerability has been