What is Kaizen?

Kaizen is a Japanese business philosophy, of continuous improvement, where company employees at all levels, work together to achieve regular, incremental improvements to the manufacturing process. It focuses on applying small, daily changes that result in major improvements over time. Kaizen has most commonly been associated with manufacturing operations, as used in Toyota, but it has also been successfully adopted in non-manufacturing environments. With the continuous strive for efficiency and growth, many companies in various industries have followed Toyota’s lead and started practicing the Kaizen philosophy.

Kai

change

Zen

good

“Today better than yesterday. Tomorrow better than today.”

Kaizen, simply means change for the better: to improve productivity, reduce waste, eliminate unnecessary hard work and humanize the workplace. In simple terms, improve everybody, every day and everywhere.

Kaizen works by reducing waste “Muda”, variation or fluctuation “Mura” and eliminating work processes that are overly difficult “Muri” (The three M’s). As a lean business practice, it succeeds when all employees look for areas to improve and provide suggestions based on their observations and experience.

Kaizen aims for improvements in productivity, effectiveness, safety, and waste reduction, and those who follow the approach often find a whole lot more in return:

All of these translate into money savings and turn potential losses into profits. You can gain the benefits of the Kaizen approach in many other working environments too, at both a personal level and for your whole team or organization.

Masaaki Imai, a Japanese organizational theorist and management consultant known for his work on quality management, stated specifically on Kaizen:

“The concept is so deeply ingrained in the minds of both managers and workers that they often do not even realize that they are thinking kaizen”.

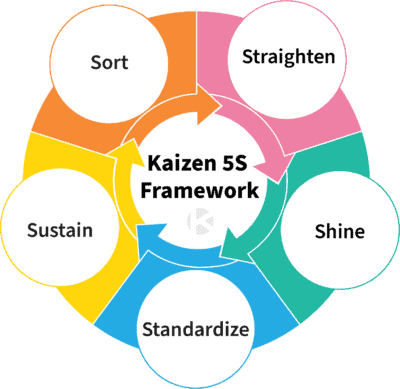

The 5s Framework of Kaizen

Another essential part of the Kaizen approach in business is the 5S framework. This workplace productivity method highlights five important factors that are intended to improve efficiency in an organization. The 5S are as follows:

1. Sort

(Seiri)

Organization

Segregate needed items from the unneeded and

discard of the latter.

2. Straighten (Seiton)

Orderliness

Keep needed items in the correct place for fast and easy access.

3. Shine (Seiso)

Cleanliness

Keep the workplace swept and clean.

4. Standardize (Seiketsu)

Standardized Cleanup

Create a consistent approach for accomplishing tasks.

5. Sustain (Shitsuke)

Discipline

Maintain established process.

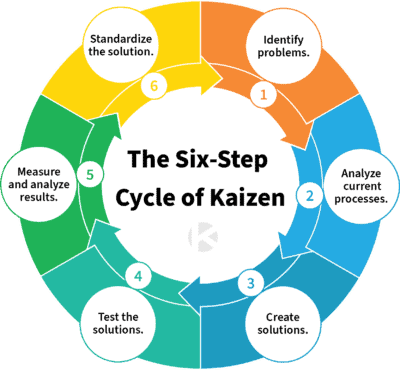

The Six-Step Cycle of Kaizen

To effectively implement Kaizen in your organization, the following six steps must be followed:

1. Identify problems.

If you are seeking to improve your business operations, it only means that there are issues within your process that need to be solved. The first thing you need to do is to make a list of all those improvement opportunities. One way to approach this is by gathering feedback from the members of your organization, especially those who are more involved in the operations, since they will have a first-hand experience of the processes and be able to specify what problems, if any, exist.

2. Analyze current processes.

Once problems and rooms for improvement are identified, the next step you should take is to analyze the processes that are currently being implemented. This is essential as this will help you identify where the problems lie and come up with ideas that you can test to be able to solve these problems.

3. Create solutions.

After reviewing your existing processes, your team can now gather ideas and suggestions on how to solve your problems and improve the processes that need to be improved. Encourage your team to come up with their own ideas for improvement so that you will have different solutions available to test and choose from. To motivate your team to be more creative and to think outside the box, consider offering a reward to those who get to provide the best solution to your current problems.

4. Test the solutions.

Once you have gathered enough solutions, you can now test each idea to find out which of these are more effective. When testing ideas, take into account the people who will be participating in the implementation of the test programs.

5. Measure and analyze results.

While testing the solutions, see to it that the progress for each test programs are being recorded and checked. It’s ideal to assign a point person for each program and make sure that everyone gets involved during the tests. This way, you can gather more ideas and feedback about the solutions being tested. Once you have collated the results for each test program, it’s time for you to analyze the results and identify which ideas are better. When choosing the best solutions, you need to take into account if they will be efficient, cost-effective, reliable, applicable and sustainable. Of course, your final decision will depend on the problems you have initially identified. See to it that each problem you have found at the start of your Kaizen process are properly addressed by the solutions that you choose.

6. Standardize solution.

Once a solution is finalized, you should now proceed to adopting the solution. If necessary, you will need to roll out and standardize a new set of processes. See to it that everyone in the organization is made aware of the new standards to make sure that everything goes smoothly.

The Kaizen process is an ongoing cycle. And as you continue your day to day business operations, see to it that you are aiming for continuous improvement and implementing the Kaizen process along the way.