The global market is changing rapidly. New industries are getting introduced daily, causing a boom in new companies, especially in the tech space. To keep up with the growing trends and fast-paced workforce large enterprises had to introduce new methodologies that will allow them to cope with that fast pace and enable them to develop cutting-edge products and services before their competitors do. One of the ways to manage large enterprise projects is through Lean portfolio management (LPM.)

Both businesses and individual customers are looking for new products that can meet their demands. With so many startups emerging along with new industries, it’s becoming increasingly hard to keep up with market demands and competition.

To keep up with the demand, companies and management teams adopt some of the popular management methodologies that allow them to stay both effective and efficient when delivering the final product to the client. Some of the most popular management methodologies are Agile (scaled Agile framework) and Lean. Sometimes, these popular management methodologies combine to create SAFe lean portfolio management. In this article, we’re going to talk about Lean methodology and explain what Lean portfolio management is.

Continue reading about Lean portfolio management and learn how you can implement it in your business management and organization policies.

Lean management originates from Toyota after World War II. Toyota aimed to do the majority of the manufacturing process while shipping Toyota vehicles to The United States, which defined how the company manufactures its vehicles today. The Lean philosophy aims to make new vehicles as efficiently as possible and eliminate waste in the process.

Also called a “Just-in-Time” system, Lean management allowed Toyota to overcome financial losses that followed the devastating consequences of World War II but also propel the company to the top of the vehicle industry where it still sits today.

What is Lean Methodology?

The key to lean methodology is to maximize efficiency while minimizing waste. Although the Lean methodology was initially introduced in Toyota, as mentioned above, it was John Krafcik, CEO of Hyundai Motor America that detailed the Lean methodology as a project management asset in an article titled “Triumph of the Lean Production System” published in 1988.

Another goal of the Lean methodology is to do more in less time. In other words, it aims to provide a framework for engineers that is both effective and efficient and will reduce time spent on repetitive and complicated tasks.

That way, the framework achieves flow optimization where engineers won’t spend time on activities and tasks that don’t add value to the project. Avoiding activities that lead to waste in Lean is of utmost importance because focusing on tasks that cause “waste” leads to overproduction and long waiting times.

Furthermore, it can also result in excess inventory, unnecessary processing, and products that may potentially go bad or have defects. Lean is still actively used in both smaller and larger businesses, as well as in the production process. It is often seen in manufacturing, software development, engineering, healthcare, and other spaces.

The Lean methodology consists of five key principles:

- Identify Value. Identify the perfect value for your product or service.

- Map the Value Stream. Design diagrams that can map your workflow and then compare it to the workflow you want to achieve in your organization.

- Create Flow. Remove the waste from your flow to match your ideal flow closely.

- Establish Pull. Only establish new work when there’s a time frame for that and your team isn’t busy finishing previous tasks. Otherwise, “pull” the product or remaining work from previous development stages into the following stages of work.

- Continue to Improve. Continue improving your workflow and adapting it to upcoming trends.

What is Lean Portfolio Management?

Lean portfolio management extends the Lean methodology by adding some new principles and features. It helps strategic management apply Lean principles to deliver better results. It helps execute different business strategies while minimizing waste.

It uses key Lean principles to connect the business strategy to execution, which is the primary goal of Lean Portfolio Management (LPM).

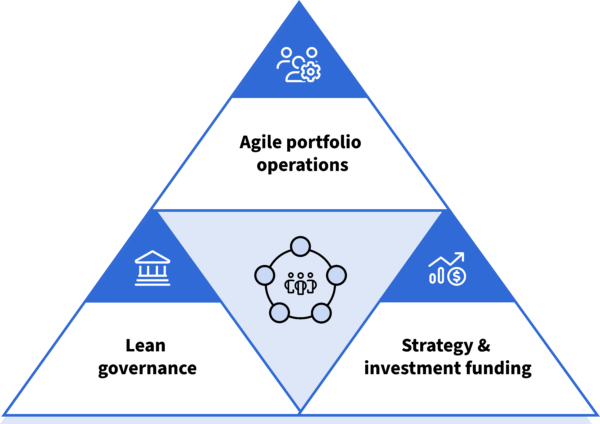

A portfolio manager that uses LPM is in charge of using Lean principles while analyzing business strategies and allocating the budget for their execution. Lean portfolio manager consists of three key dimensions:

- Strategy and investment funding. Make the necessary alignments in the portfolio budget so that it’d meet the business targets.

- Agile portfolio operations. Allow the Agile teams to easily and quickly adapt to the changes so that they can solve the problems that may arise as a result of those changes.

- Lean governance. Make boundaries for expenses, audits, and investments for better forecasting and problem-solving.

Keep in mind that Lean portfolio management is not so easy to implement, and it will take time for your team to completely adapt, especially if your team is used to traditional portfolio management. Nevertheless, if you persist through the struggles of adapting to the new management system, it will allow your team to do more, while minimizing expenses and loss.

Why Lean Portfolio Management?

Below, we detailed some benefits of using Lean portfolio management for your teams, regardless of the industry you work in.

It Allows You to Maximize Value

Lean portfolio management allows you to visualize the ideal product that will bring your company more value through the eyes of the customers. By taking the role of the customer, you will be able to see the potential flaws of the current product or service you’re offering and make the necessary improvements.

A clear picture of the product can then be used to align different teams within the organization and help them adapt to the new development practices to deliver more value than the previous product.

Time to Market

Time to market refers to the length of time needed from visualizing the product idea to its delivery to the customer. In commerce, this time is often the gap between being the industry leader to being the second or even third competitor in the competition. Companies need to take the best advantage of this time to deliver the best results.

The value-oriented practices of Lean portfolio management can help improve the time to market because all its core principles are focused on delivering value and what matters the most to the customers, while focusing on preventing loss. Additionally, you will also be able to manage the budget without making excess expenses while in the race for the best product.

Quick Pivots

When working on large projects or managing a large portfolio system consisting of several projects, it becomes incredibly difficult to rotate and make urgent changes deep into the process of development of the final product or service.

However, Lean portfolio management is flexible and allows team members to quickly pivot when drastic changes in the industry take place.

You can achieve that by organizing your employees into adaptable and cross-functional teams that can change their roles when conditions change. Coordinating such teams may be challenging at first, but Lean portfolio management is equipped with principles that make it possible.

Product Fit

Lean portfolio management is based on Minimum Viable Product Iterations, which means that the final product will be more suitable for the larger demand.

It also allows the team to kill off the product or service in the early development stages if they see that the final product won’t be suitable for the larger demand and will take too long to be developed into a final product that has already been outdated.

How to Implement Lean Portfolio Management?

To achieve lean portfolio management, you need to implement it correctly. The following steps detail how to implement lean portfolio management to successfully lead your team and ensure prompt delivery of final products and services.

Find the Leaders

While team members make one of the most important factors in product delivery, it wouldn’t be possible without the right leaders who empower the teams and lead them through struggles and challenges.

Team leaders help connect the strategy to the execution for specific parts of your company and each team. They’re also in charge of recruiting the right team members that are suitable for specific team roles.

Find Funding

Getting your team members and leaders assembled is just the first step to delivering a perfectly lean product. Without funding, your team members can’t receive appropriate compensation for their hard work, nor cover the expenses of managing the product if it’s a digital type of product or service.

The first thing you will need to do is ensure you identified the key products to focus on, as well as identify which projects cost the most. Then, you can allocate the funds to each product.

Project and product managers will be key assets in allocating the budget appropriately, as they will know which parts of the project require the most financial attention.

Build an Operating Structure

If you’re managing large organizations, chances are that different teams will take different approaches to implementing lean portfolio management. Your job is to identify the needs and requirements of different teams in your organization and meet them.

Your job is to ensure that the teams work in an operating structure that meets their needs and expectations, and where they can envision a management system that is aligned with the lean portfolio management principles.

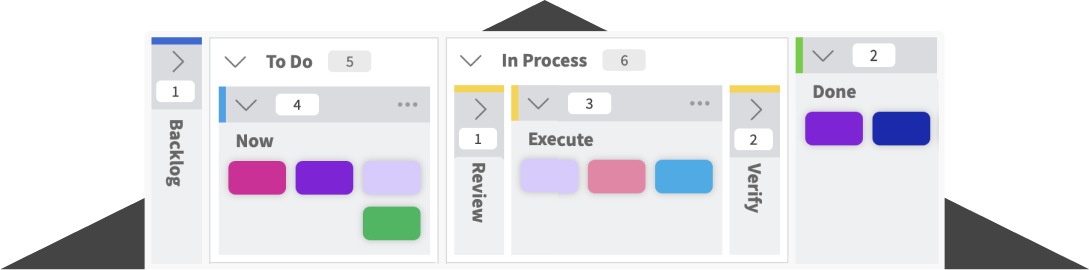

Create a Lean Workflow

The next step is to create a lean workflow. You do that by eliminating everything that can lead to loss and hinder the workflow. Additionally, the team will eliminate all the efficiencies from the projects and focus on delivering the best results. One way of doing this is by establishing an effective pull system that will notify the team members that all tasks are complete and you can move to the next stage of project development.

Upgrade

With LPM implemented in your workflow, you will constantly need to improve in order to deliver greater results. That also includes new decision-making and incorporating guardrails that can help you upgrade your work when necessary and make sure that the workflow is running smoothly. Your team needs to be flexible to changes and adapt to them quickly while maintaining clarity.

Celebrate New Milestones

Every time you and your team visualize a new project and the development and delivery go smoothly, it’s of utmost importance to praise and celebrate success. Project development and portfolio management are rewarding processes and it’s important for the team to feel valued and appreciated. This will further motivate them to work harder and yield even better results in the future.

Conclusion

Lean portfolio management is an upgrade to lean methodology which brings all its core principles and improves them for reaching even better results while eliminating efficiency. The best way to implement it is by using productive Kanban boards and Gantt charts.

Are you interested in creating your first Kanban board to implement the LPM? Register with Kanban Zone and immerse into a whole new world of opportunities to make your portfolio management workflow smoother and more productive!

Learn to Work Smarter, Not Harder!

Get our top articles weekly.

Table Of Contents

Discover many more posts…