The Kanban Lead Time and Throughput Conundrum

Kanban’s background in product development and maintenance might focus on Lead Time where being quick to market is important, but many companies just need more things to be done in less time (rather than faster) and cheaper, which is where improving Throughput comes in.

-Kurt Häusler

A little while ago, I ran across a statement from Kurt Haüsler that you can read just above. What an awakening. I then realized that all my knowledge regarding Kanban was really focused on Lead Time. This is what the Kanban method is all about. Everywhere, Kanban’s basics is taught with Little’s law. You get to understand the effect of Work In Progress (WIP) on Lead Time and voilà! That sums it up. As for Throughput, it is merely the plug-in figure in Little’s law for the Kanban method.

There is literally nothing to support Throughput management: no class and no training on the Kanban market. Nothing. This is when I started to look for thought leadership on the topic.

I then ran into Steve Tendon’s Tameflow. Then I bought his book. The rest is history. I am now a Tameflow Kanban trainer and we do Throughput Kanban; and we are the only ones.

TameFlow Kanban Times

The first thing we need to know to get good Throughput is a clear understanding of flow efficiency. And this is where I think I witnessed the highest degree of confusion in the Kanban method. Lead time is used as the denominator in many illustrations. How can you be efficient at doing something when you are not in control?

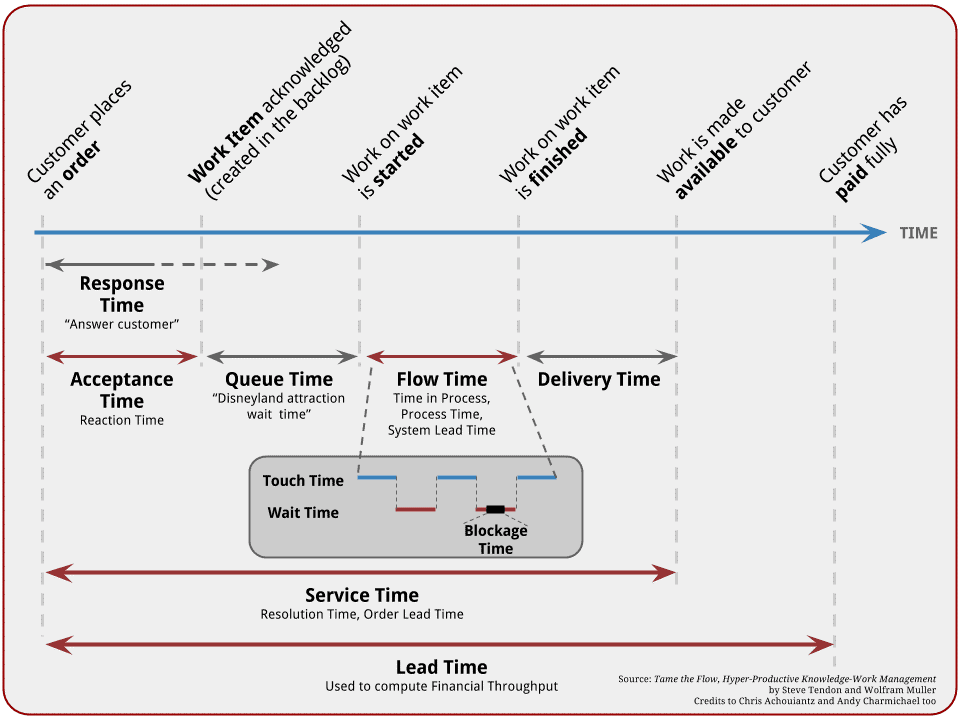

It is time to get our Kanban flow ‘times’ on a well articulated scale. For this I refer you to figure 1 below:

Lead Time is not under our span of control. It is not even under our sphere of influence. If you know your Kanban roots from Dr Eli Goldratt, you know you cannot be efficient at things you do not control. It is nonsensical.

Lead Time is not the right metric for the denominator of Flow efficiency. Bottom half of illustration: Wait time + Work time while in Flow time is the proper denominator!

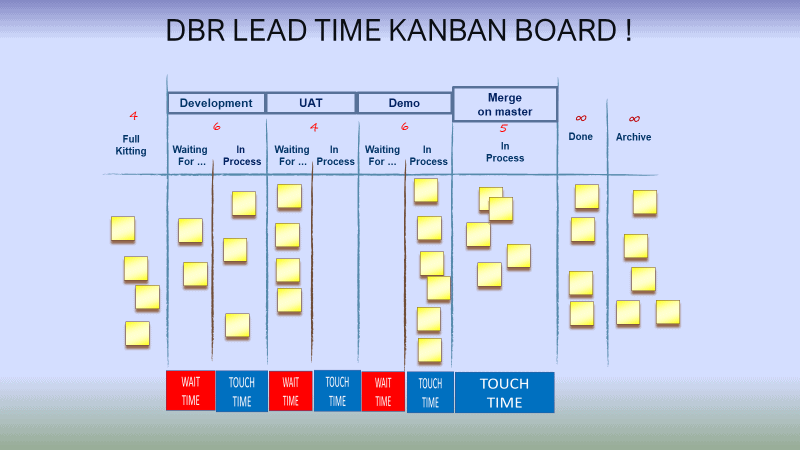

Flow efficiency belongs to Flow time where you have full control as illustrated in figure 1. Two states are witnessed: Wait time and Touch time. No Disneyland ‘time’. The proper denominator for Flow efficiency is therefore (Wait time + Touch time) while in Flow time where you are in control of your process. The proper numerator is Touch time. You will notice that traditional Kanban boards do not spell these two states explicitly on their Kanban boards. When you look at figure 3 below, you see that DBR Kanban boards are pretty explicit about Wait time and Touch time. Nothing else appears!

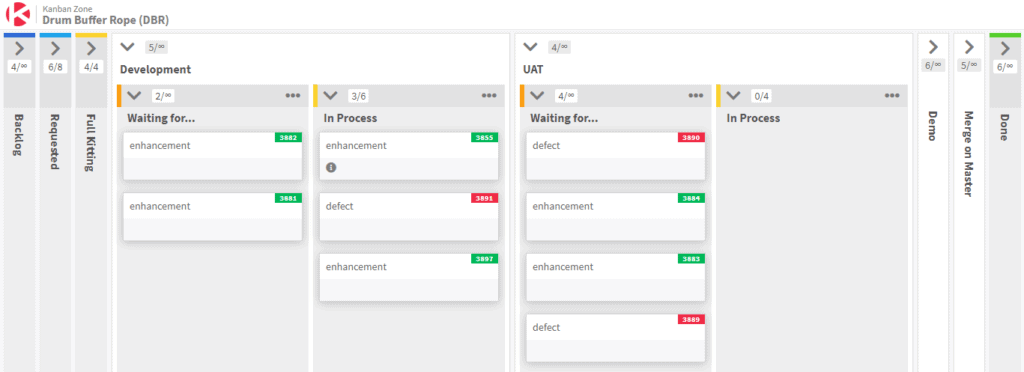

If you notice the alternation of Wait times and Touch times in figure 3, it is like a natural phenomenon of… flow. It is also quite well geared to be in columnar forms like the ones we find on Drum Buffer Rope (DBR) Kanban boards. Let me show you, with the illustration below, the Drum Buffer Rope (DBR) Kanban board that I was able to create in a flash using Kanban Zone’s software

You might be asking yourself why the discussion it so centric on Flow efficiency. It is because Flow efficiency is closer to Throughput than it is to Lead Time. This paradigm is not reflected on Lead Time Kanban boards. It needs to change.

Drum Buffer Rope (DBR) Kanban Boards and Buffer Removals

The Drum Buffer Rope (DBR) Kanban boards have many novelties. Some of which are psychological and others scientific. For first, you only see Wait states and Touch states column statuses. That’s good. It is visually aligned with Flow efficiency. Not so for traditional Kanban boards. This is why all traditional Kanban boards buffers of the form ‘Ready’ columns as described below are not required:

- Options from Upstream

- Releases (storing in front of a big batch)

- Waiting for external

- Capacity Constrained Resource (CCR) bottlenecks

- Non-Instant Availability (NIA) bottlenecks

You will notice that all these Kanban buffers are apposed right after a ‘Done’ state – which is a Wait state – to another ‘Ready’ state – which is another Wait state – something that lacks elegance from an architecture point of view.

These buffers belong to Lead Time Kanban boards. They do not belong to Drum Buffer Rope (DBR) Kanban boards!

Another reason why these ‘Ready’ buffers are bad is a tad scientific and brainy. For that we need the help of our basic Agile and Lean decision filters!

Agile Decision Filter:

- Are we making progress with imperfect information?

- Treat WIP as a liability!

- Trust brings down transaction costs

Lean Decision Filter (in the order describe below):

- Value trumps flow – Expedite at the expense of flow to rate value

- Flow trumps waste elimination – Increase WIP, if required to maintain flow, even though it may ad waste (INCREASING WIP DOES NOT MEAN TO ADD ‘READY’ BUFFER COLUMNS!)

- Eliminate waste to improve efficiency – Do not pursue economies of scale

The one common lesson we can draw from these decision filters is that WIP is bad. WIP is a liability and is linked to resource efficiency. High WIP bequests high queue time. High queue time bequests high Wait times.

Having buffers to make your Wait times at home comfortably everywhere on a Kanban board means only one thing: You are treating them as assets!

In the cost accounting world, wait time means resource efficiency. It is an inventory that is valued. It is what needs to be stricken out from traditional Kanban boards. (Ready columns and Done columns)

In the Throughput accounting world, wait time is less throughput and against Flow efficiency. It is inventory piling up and that is a burden. This is why we minimize the occurrences of Wait states in DBR Kanban boards to get better metrics among other things.

To conclude there are no technical or psychological benefits to maintain ‘buffer/ready’ columns, or any type of “dampening” columns for that matter, as the time spent there has deep psychological impacts on the way a knowledge worker goes about his/her work.

It is a mindset. Wait time is always wait time. But what do you (and everybody in the organization) understand wait time to be? An asset or a liability?

Get rid of those!

Drum Buffer Rope (DBR) Kanban Boards and Getting rid of the Done Column

Getting rid of the ‘Done’ columns is a bit of a psychological challenge. But look at it this way:

Preferably, you should never do flow-backs. But the Drum Buffer Rope (DBR) Kanban board design helps manage flow-backs. Companies do flow-backs, especially at the start. Traditional Kanban boards with the ‘Done’ column sort of disabled this eventuality. How can you send back something to a previous ‘Done’ state? Doing this may seem trivial, but you are in fact distorting flow metrics! The problem with the traditional Kanban board layout and the intermediary “Done” columns after a working state, is that you send work back to where? Then… try again… send work back to an effective working column? That works correctly only if the work item has the top priority, which very seldom happens with flow-backs. So, you end up putting the item in a working column while the item is really waiting for the worker. The flow metrics are distorted. You are recording it as touch time (if you are recording wait/touch times at all), while in reality it is wait time. Flow efficiency figures will appear much better than what they really are.

If the upstream (“to the left”) resource you are requiring to work for a flow-back is not available, you must leave the ticket where it is. When an item gets stuck because it requires upstream resource (or other resources) then all of those resources should “swarm” onto the item if they are free, while the item remains in the column where it was stuck. We want items to leave ASAP.

Where Have The Wait Times And Blocked Times Gone?

Obviously, there will always be wait times or blocked times or idle times or feedback delay times while in Flow time throughout the process. Such is the nature of knowledge work. And it is a sizable chunk of the work.

They have not disappeared because of a new board design. But from a psychological and motivational point of view, we are in a different beat, a new paradigm. Let me explain.

You see, when you are in a ‘Waiting for …’ state, you are signaling to the next process that you are ready. It creates positive tension. There is work. But not too fast. The workers in the ‘In Process’ state – Touch time – know that they have to minimize Wait time. To that end, they must keep WIP under control and be in a ‘Stop starting, Start finishing’ mind frame. So, there is friction between the two states. A friction – positive tension – that you do not find in traditional Kanban boards where Wait states are tolerated everywhere.

And we have a new weapon, the ‘Full kitting’ column. It is not a ‘Ready’ type of column that says ‘I am ready for the next step’. It is a full preparation for the entire process to allow you to act Just in Time as you progress. You need to have your process fully understood before starting to maximize Touch time while you are ‘In Process’.

You will notice a sharp departure from the traditional ‘In Progress’ Lead Time Kanban boards columns. The reason is quite easy to understand. It is more accurate to say ‘In Process’. You can be ‘In Process’ and very well not be making any ‘Progress’!

Drum Buffer Rope (DBR) Kanban boards are very popular in the Netherlands and have been for the last seven years. It has passed the test of time and now you can reap the benefits in the marketplace.

This was a guest blog. Please review our guest blog disclaimer.

Learn to Work Smarter, Not Harder!

Get our top articles weekly.

Table Of Contents

Discover many more posts…