For businesses to ensure longevity, they need to continuously satisfy customers. But customer satisfaction has been more difficult to target in the past decade because of the rise in competition, globalization, and technology. Companies can’t rest on their laurels thinking that their customers will always go back to them.

Consumers today have more power than ever before. They have access to a variety of options for a product or service. Hence, they will choose the best one that fits their needs. And this is why quality is now, more than ever, a critical aspect of any business operation. To satisfy customers, companies must ensure that quality is built into every step in their value chain.

And when we talk about quality, two concepts pop up into the conversation: continuous improvement and quality control. These two have become staple topics in project management and product development discussions, so much so that they have become buzz words. Sometimes, they’re even used to mean the same thing. But it’s important to know what they are and how they can help companies enhance their competitive advantage.

What is Quality Control?

Quality control is a set of procedures and policies that are used to ensure that a manufactured product or performed service adheres to the company’s defined set of quality standards and criteria and the requirements set by the customer.

The perception of quality control has changed over the years. In the past, it was seen as an additional step towards the end of the production process to check that everything’s good to go. Now, the mindset towards quality control has changed into something more integral to each step in the process.

Quality is not something you work towards the end, but something you build upon on every step of your value chain. This mindset shift has allowed companies to solidify their pursuit of higher levels of customer satisfaction.

What is Continuous Improvement?

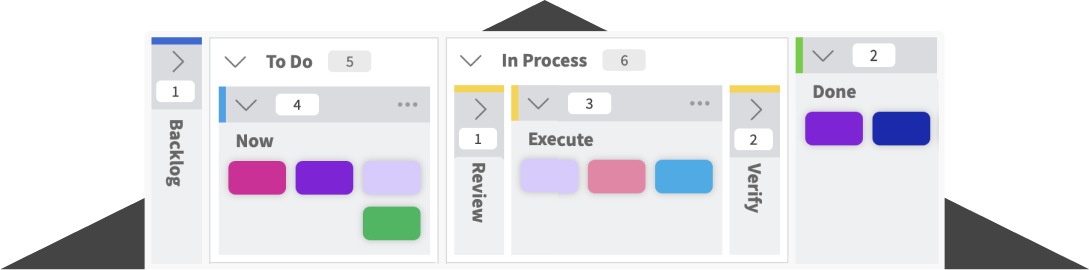

Continuous improvement is the method of finding opportunities to streamline processes and reduce waste. It is an iterative process as there is the realization that things can be better. Your processes are not meant to be fixed. Circumstances such as changing market demands, organizational goals and targets, technologies, and process inefficiencies can push you to improve upon your current processes.

While there are many continuous process improvement methodologies available, like Kaizen, DMAIC, and Deming’s PDCA Cycle, it is important to emphasize that it is not only a method but a mindset. It is by developing a culture of continuous improvement will companies reap lasting benefits that will help them thrive.

How Continuous Improvement and Quality Control Work Together

Based on our evaluation of both, we can conclude that quality control and continuous improvement work hand-in-hand. Quality control is more focused on ensuring the current deliverable satisfies the quality standards set by the company and its customers. On the other hand, continuous improvement is focused on creating organizational and process changes to enhance how the product or service is developed and delivered.

Quality control provides inputs that can be used by teams for continuous improvement. For example, it is through quality control that defects and inefficiencies are identified by teams. The resolution is not only to prevent defects from getting out of the pipeline. It’s also important that the causes of these defects are eliminated. And this is where continuous improvement plays a role. The team analyzes the problem at hand on a deeper scale and creates solutions to eliminate inefficiencies and waste.

The outcome of continuous improvement then becomes new procedures or policies in the company’s quality control plan.

Build Quality in Every Step

Quality control and continuous improvement should be at the forefront of any company’s operational and strategic plan. By integrating these into your process and culture you can achieve better levels of customer satisfaction. But for this to work, everyone in the organization must buy into the company’s quality goals. Quality should be everyone’s responsibility.

Don’t let quality breakdowns to slip. You have the power to control your process and level of quality. Regularly check your process metrics and spot any deviations to your standards.

Regularly gather data about your process performance and analyze where you can improve. A mindset built upon continuous improvement will translate in the way you work. Quality control and continuous improvement will then become second nature to your organization.

Learn to Work Smarter, Not Harder!

Get our top articles weekly.

Table Of Contents

Discover many more posts…