In today’s competitive work environment, companies often need to look at strategies for improving their processes aiming at delivering high quality products or services.

Among the diverse methods available that help companies accomplish this goal, the Agile Kanban method has been used over the years in many different industries and fields of knowledge.

Through the utilization of the Agile Kanban method, important metrics associated with the process under consideration can be evaluated as for example, lead time, cycle time, throughput, aged work items and many others.

In this article, the focus is oriented towards one of the most relevant metrics which is possible to be obtained through the Agile Kanban method: the metric called flow efficiency. You will understand how to measure it, and why you should do it.

The Flow Efficiency Metric

The metric flow efficiency is a process indicator that shows the proportion between the value-added time and the lead time of a given process. Therefore, in order to correctly understand what flow efficiency means, it is important to comprehend the concepts of both value-added time and lead time.

Value-added time refers to the amount of time in which work is truly being carried out on a work item. For example, value-added time is often associated with tasks that:

- alter either the product or service that the customer requests;

- improve some feature or function to the product or service;

- allow the customer to achieve competitive advantages;

- are accomplished without rework.

On the other hand, non-value-added time is often associated with waste tasks within the process, which therefore should be reduced or eliminated.

The process lead time consists in the total required time duration from the exact moment in which a work item enters the process to the very time the work item is delivered to the customer (internal or external). In this sense, the metric lead time does not differentiate between tasks regarded as either value-added or non-value-added. If the process lead time is high, it indicates that the process has many wastes and should be improved.

Having these concepts in mind, in a practical sense, the metric flow efficiency corresponds to the ratio between value-added time and the lead time, as shown in Equation 1.

Equation 1 shows that it is possible to increase flow efficiency when the value-added time gets higher or if the process lead time is reduced.

In the field of Lean Manufacturing and continuous process improvement, flow efficiency is analogous to the metric Process Cycle Efficiency (PCE).

How to Measure Flow Efficiency

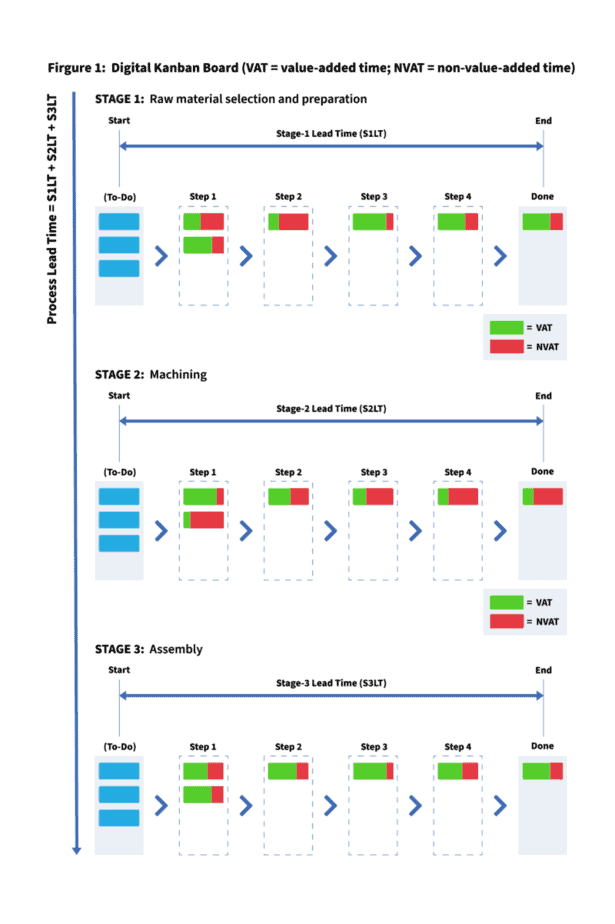

Flow efficiency can be measured by using the Agile Kanban method through appropriate digital Kanban boards. This is possible as digital Kanban boards are able to precisely measure and store the time related to tasks being actively carried out (value-added time) and those tasks which are stopped or waiting (non-value-added time) throughout the process. Figure 1 shows a digital Kanban board used for example in a manufacturing process for the production of industrial components.

The Kanban board shown in Figure 1 consists of three sections which schematically characterize the stages of the particular manufacturing process. The process begins at Stage 1 and it ends at Stage 3 according to the flow of a pulled process, that is, each process stage begins only when its predecessor stage has already finished. The manufacturing process flow over time is represented by the blue arrow on the right side of Figure 1.

Each process stage shown in Figure 1 (i.e. Stage 1: Raw material selection and preparation, Stage 2: Machining and Stage 3: Assembly) can be interpreted as a singular process itself which in turn is composed of particular consecutive steps represented by the vertical dashed columns.

This digital Kanban board allows obtaining many important process metrics, as for example, process lead time as well as the value-added time (VAT) and non-value-added time (NVAT) for each work item throughout the process. Based on such process metrics, it is possible to evaluate the flow efficiency of the process as shown in Equation 1, thus allowing the analysis of possible process bottlenecks and other kinds of waste that arise in the process. By eliminating or reducing process waste it is possible to continuously improve the process.

Why Measure Flow Efficiency?

Measuring flow efficiency allows you to better understand your process as a whole as well as its performance over time. By quantifying the process performance, it is possible to realize the required actions that need to be implemented aiming at delivering stable and fast products or services to the customer. This consequently leads to enhanced customer satisfaction.

An additional important aspect related to measuring your flow efficiency is that it can help reveal how much waste is embedded in your process. By understanding the causes behind those wastes, you can try to reduce them, or even better, eliminate these causes, thus leading to process improvement.

Learn to Work Smarter, Not Harder!

Get our top articles weekly.

Table Of Contents

Discover many more posts…