Genchi Genbutsu

What is Genchi Genbutsu?

The majority of lean concepts known today take roots from the Toyota Production System (TPS). You may think that genchi genbutsu is just another Japanese lean manufacturing term like kanban, kaizen and muda, however it is the core of the automotive giant’s way of working.

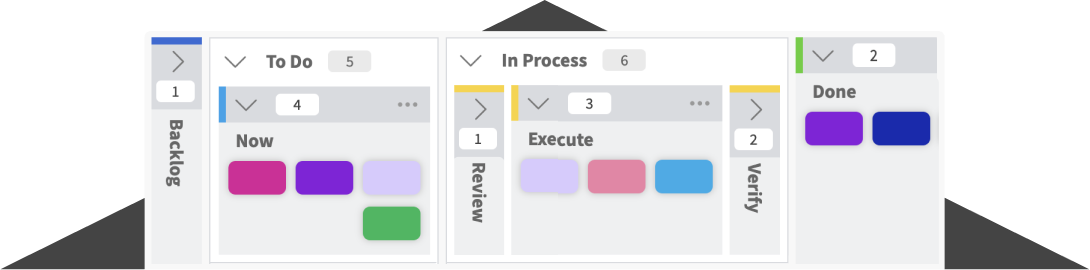

The Toyota Way is a set of principles, values, and behaviors that guide TPS and their management approach. Its two main pillars are Continuous Improvement and Respect for People. The three main building blocks of Continuous Improvement are Challenge, Kaizen, and Genchi Genbutsu.

Genchi Genbutsu – Toyota Production System – Source: Toyota.co.uk

Let’s move the spotlight onto genchi genbutsu. What exactly is this concept?

In Japanese, genchi means “actual place”, while genbutsu means “actual thing.” In the Toyota Way, this concept means “to go and see” or even better, “going to the source.” It is the belief that to make informed decisions and know how to appropriately solve problems, one must first experience the situation at hand. This means having to actually go to the source and see how the process is working.

At Toyota, managers are expected to immerse themselves in operations by becoming familiar with production processes and how people are completing the work. It is through these efforts that they are able to understand the dynamics of the business operations better.

To practice genchi genbutsu successfully, one must be embedded in the process and actually perform the work.

Why do we need to practice Genchi Genbutsu?

Practicing genchi genbutsu allows businesses to focus on facts and minimize biases that can be derived from reports. Teams are able to better visualize the problem to pinpoint the cause in a much faster and accurate manner. If teams rely heavily on reports, their interpretation can be misled, which will translate to poorly derived and executed decisions.

Genchi genbutsu allows teams to reconcile data with front-line activities, by merging both data and experience, businesses are able to derive facts about a problem with a higher level of confidence. This translates into developing better recommendations and ideas that improve the process or solve the problem.

How do we practice Genchi Genbutsu?

Genchi genbutsu is a way of doing things, a habit that must be practiced by everyone in the organization.

Before you begin practicing genchi genbutsu, you must first identify your genchi. This is the place that that has your genbutsu, or the source of the problem. Once the source is identified, there are various ways to immerse yourself in the process including:

- Hands-on Experience – Embed yourself in the process by being one of the actual process actors and experience first-hand how value is created and waste is generated.

- Observation – An outside view of how work is executed can provide a different perspective. Nuances and inconsistencies can be identified in processes that people accustomed to doing the work would fail to recognize.

- Interviews and Surveys – Get to know more about how people think they are doing the work by conducting interviews and surveys. This can also help you identify discrepancies or gaps due to human bias or understanding.

- Reports – Consider historical data and past reports that have been generated about the process. However, we recommend double-checking reports by using at least one of the more immersive approaches previously mentioned. This will help reconcile what’s on paper with what’s in the “real world.”

You are not confined to doing one of these activities exclusively. It is encouraged to use a combination of techniques to provide a more accurate assessment of the problem. Don’t overdo it, as you might create unnecessary work. Determine which activities make sense to the situation and apply those.

We also recommend practicing genchi genbutsu regularly. Don’t wait for problems to occur. Be proactive in looking for improvement opportunities.

Genchi genbutsu isn’t only a manager’s responsibility. Once ingrained in your company’s culture, employees become aware of their work environment and actions. This will enable them to naturally help diagnose problems and spot improvement opportunities.