Value Stream Mapping (VSM) is a valuable tool for process managers and teams alike. The pursuit towards a lean process starts with the evaluation of the current state process and identifying wasteful activities. If you’ve seen a value stream map before, you’d know that there are many symbols used to make one. Now, don’t be scared if you haven’t done a VSM before. We have rounded up the list of value stream mapping symbols you need to know to create your own.

What is Value Stream Mapping?

Before we enumerate the value stream mapping symbols, let’s first discuss what value stream mapping is and why you should use them.

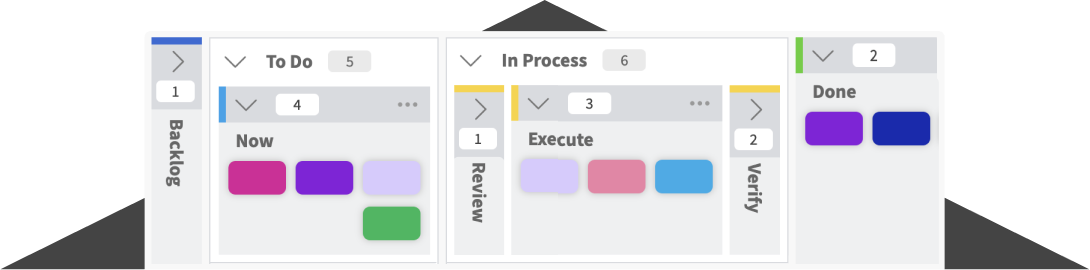

Value stream mapping is an effective lean manufacturing technique to document, analyze, and improve business processes. The output of value stream mapping is a value stream map. It shows the flow of materials and information that are involved in delivering a product or service to a customer. The goal of value stream mapping is to show all the steps that go into the customer value delivery chain and expose its inefficiencies. When inefficiencies have been detected in the value stream map, corrective action is then implemented on the step or part of the process where the problem occurred.

Corrective action can be in different forms and is mostly dependent on the type of waste or problem that is experienced by the process. Some of the most common corrective actions applied in value stream mapping are the following:

- 5 S

- Standardization

- Visual controls or displays

- Layout/Work Cells

- Balancing

- Leveling

- Quick changeover

Read more about value stream mapping to learn what it takes to create your own.

While value stream mapping is more commonly used in manufacturing, it can be used for other types of business processes with materials and information flows.

Value Stream Mapping Symbols and What They Mean

Now that you know what value stream mapping is, let’s get to know the value stream mapping symbols and when to use them.

Value Stream Mapping Process Symbols

Value Stream Mapping Material Symbols

Value Stream Mapping Information Symbols

Value Stream Mapping General Symbols

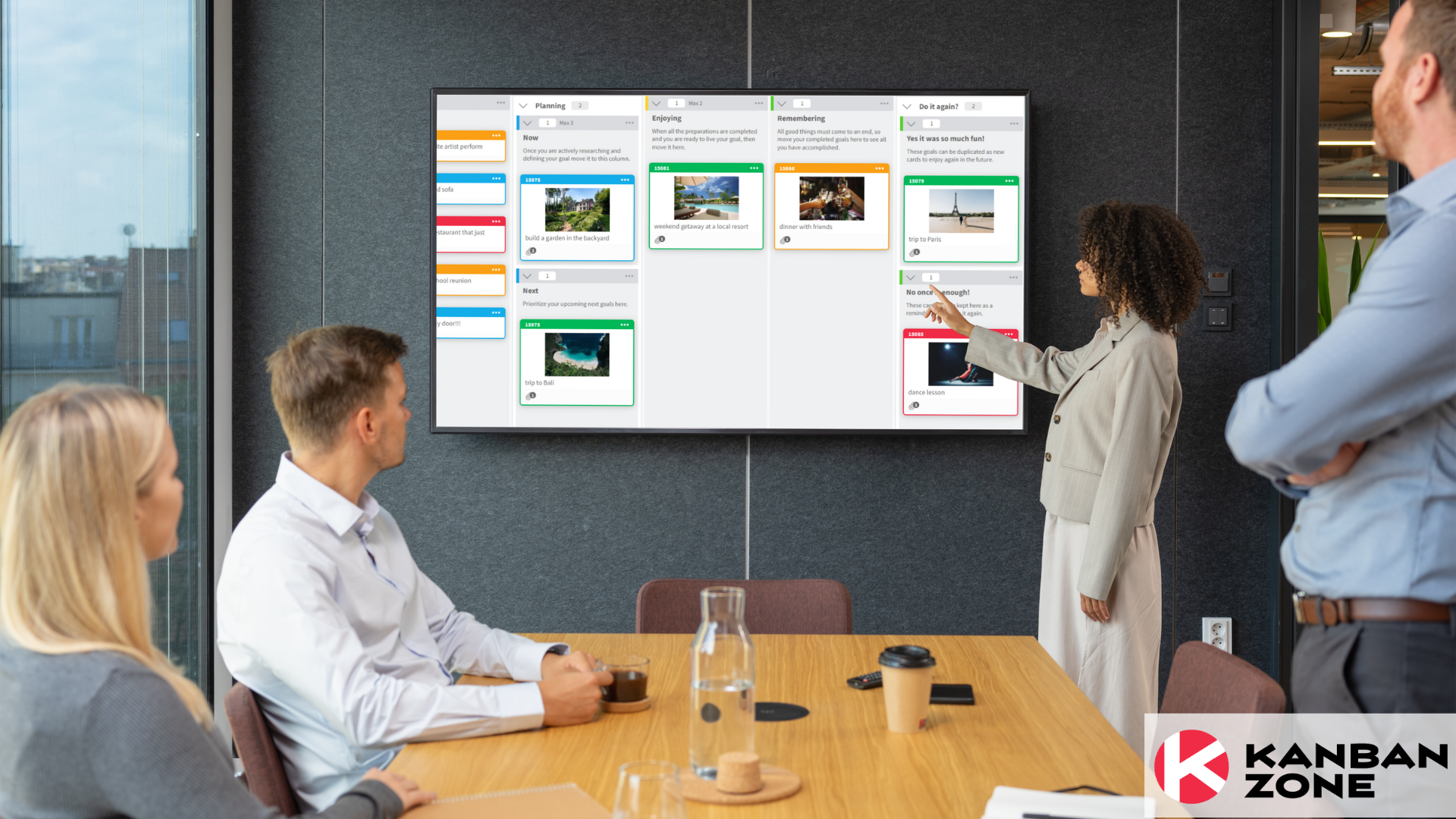

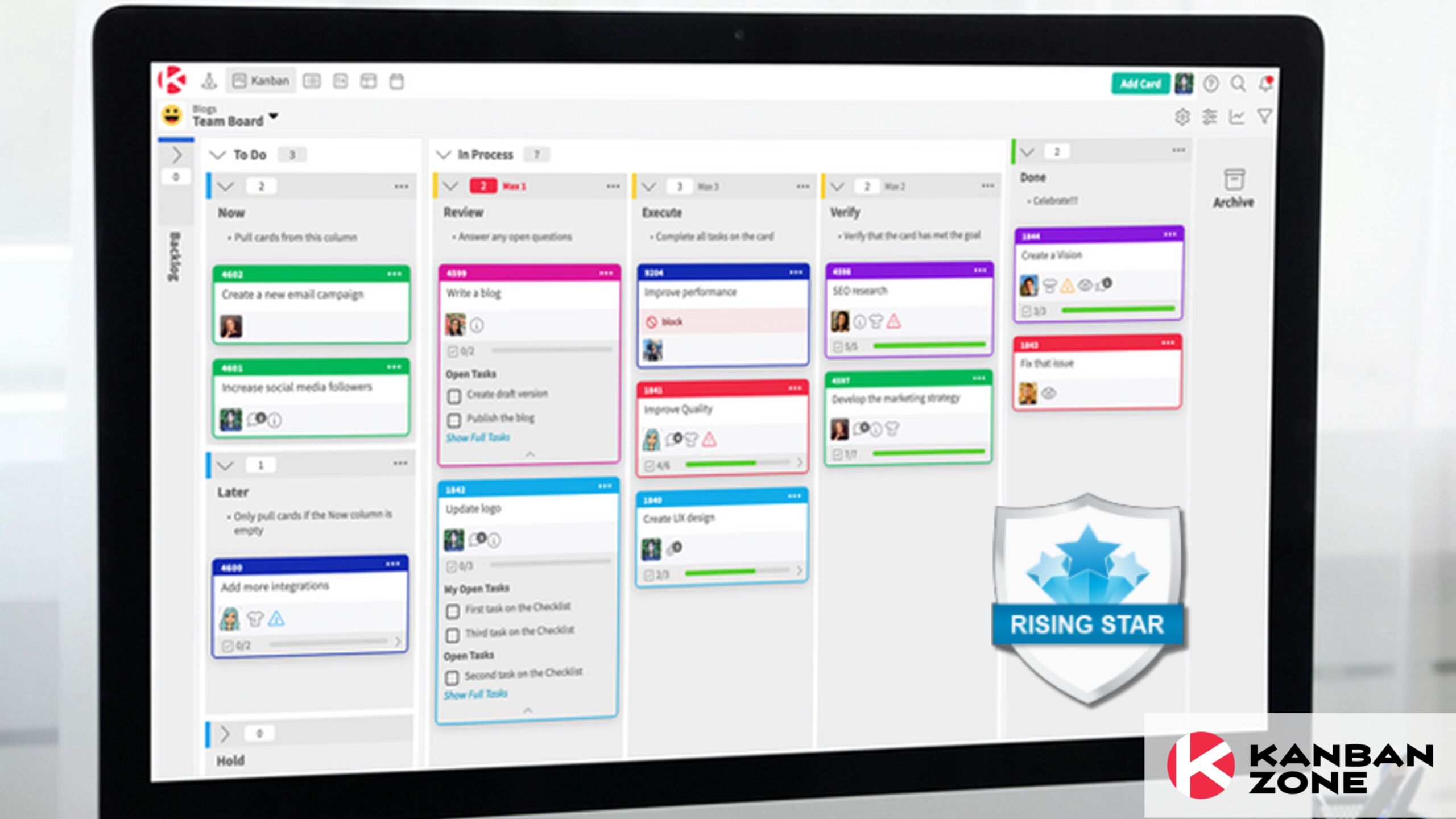

Creating a Lean Process using VSM

Value stream mapping is an effective tool to gain control of your business process. When venturing into a value stream mapping activity with your team, have an open mind and be prepared to dive into the nitty gritty of your processes. Interview your process owners and find out about your warehouse management strategy. Go directly to your assembly lines and production floors. See the process for yourself by performing genchi genbutsu. Then use the value stream mapping symbols to create a visual and accurate representation of your full value stream.

Once you have your current state value stream map, start identifying opportunities for improvement and kaizen bursts. Maximize the flow delivered value that you’re getting out of your value streams with your value stream maps as a guide for creating a lean process.

Learn to Work Smarter, Not Harder!

Get our top articles weekly.

Table Of Contents

Discover many more posts…