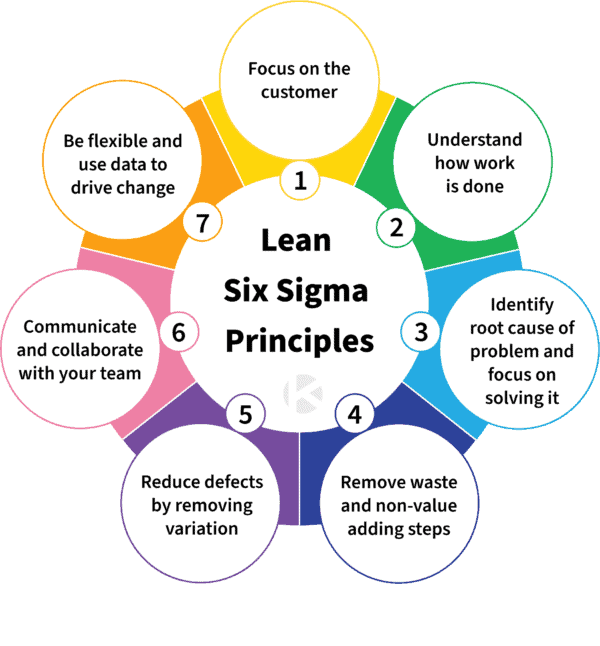

Lean Six Sigma is a fusion of two of the best management techniques – the Lean method and Six Sigma. Applying Lean Six Sigma allows businesses to improve overall efficiency, productivity, and customer satisfaction. This is achieved by eliminating waste, reducing variation, decreasing defects, and removing non-value adding activities in the process. It allows better quality products and services and faster delivery. But Lean Six Sigma is not a plug-and-play method. More than the process involved, it requires a paradigm shift in business operations. It needs to be part of the organization’s culture. Establishing a culture of continuous improvement requires the right foundation and mindset. Following the seven Lean Six Sigma principles enables businesses to ingrain the methodology in its organizational culture and reap sustainable success.

The Seven Principles of Lean Six Sigma

Focus on the customer

The goal of Lean Six Sigma is to provide value to the customer. To do this, companies must know what value means from the perspective of the customer. This also requires establishing a clear definition of quality that’s based on the customer’s requirements and expectations.

Understand how work is done

We can’t improve something we don’t understand. While documentation certainly helps, it’s equally important to see the work in action. Lean techniques like genba and genchi genbutsu allow process improvement teams to see where and how the work is done. This enables them to scan the work environment and observe the work as it happens. This will help teams to more accurately map the value stream.

Identify the root cause of your problem and focus on solving it

When doing process improvement work, it’s easy to get caught up on making solutions immediately and skip understanding why the problem is experienced. This is a common mistake of teams when they go ahead and make changes to the process without thoroughly examining the problem first. Gathering process data that shows where the problem lies allows teams to concentrate on improving that area first and get to eliminate the root cause of the problem.

Remove waste and non-value-adding steps

Removing waste and bottlenecks in the process is another important part of the seven Lean Six Sigma principles. Waste removal allows work to flow smoothly, which increases the value churned out of the process. It’s necessary to understand what type of waste is encountered to know how to eliminate them. Understanding how and how much waste is produced combines both Lean and Six Sigma analysis to come up with a viable solution to measure and effectively eliminate waste.

Reduce defects by removing variation

By reducing variation and laying the groundwork for standardization, companies can be more cost-efficient while meeting customer satisfaction. As a part of the Lean Six Sigma principles, this allows the process to be predictable and controlled. Implementing standard processes and procedures, checklists, forms, and templates are some ways to establish standards at work. Making sure everyone is trained on how to properly execute the process is also important. Automation of any repetitive tasks should be done whenever possible. Regular review of process performance will also help teams stay attuned to their process and change when needed.

Communicate and collaborate with your team

A common problem when Lean Six Sigma projects are implemented is that the project leaders (i.e. those with Six Sigma certifications – Green Belts and Black Belts) work on their own to solve the problems. To get to the root cause of the problem and create effective solutions, you need a cross-functional team composed of key persons who know the process and know how to apply Lean Six Sigma solutions. This allows teams to have a big picture view of the process and assess the impacts of proposed solutions.

Be Flexible and Use Data to Drive Change

People naturally resist change especially when it’s a big shift from the norm. Lean Six Sigma projects can bring about minor to major changes to processes which can cause anxiety to employees. By providing context and using data to explain the changes, employees will be more receptive to participate. Any change should be backed by data to show why it’s needed and how the change has impacted the process and the people working on it.

Train Your Team

Applying these Lean Six Sigma principles in your organization requires proper training of your employees. You might be the expert when it comes to the intricacies of the Lean Six Sigma concept. But as far as the business processes go, your employees and teams are the ones doing the work. Improving business processes should be a collective effort from everyone in the team. By training your team about the Lean Six Sigma principles and techniques, they will have a different perspective when it comes to doing their work and will be more receptive of non-value adding activities, wasteful work, and inefficiencies in the processes. They will be proactive to continuously improve the business which is the ultimate goal of Lean Six Sigma.

Are you ready to unleash your full potential with Kanban?

Start your journey of self-development with your Personal Kanban, or set up a Portfolio Kanban system to visualize your ideal workflow.

Leverage our team of Kanban experts and receive our Kanban email educational series.