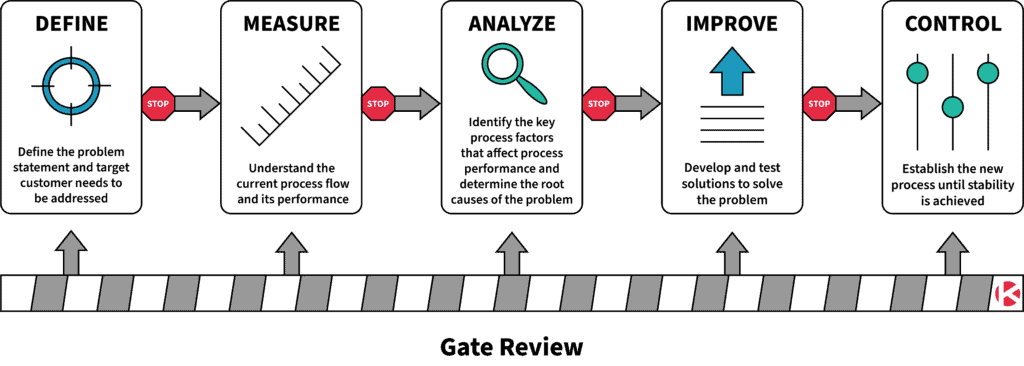

Lean Six Sigma is the fusion of two process improvement methodologies – Lean and Six Sigma. At the heart of Six Sigma is a 5-phase process, called DMAIC, that guides teams on how to effectively tackle defects and inefficiencies in their process. DMAIC stands for Define, Measure, Analyze, Improve, and Control. Here we’ll dive deeper into how the DMAIC process works and what teams should expect when applying this technique.

Lean Six Sigma DMAIC Process Defined

The DMAIC process was developed and first used by Motorola. They used qualitative and quantitative data to get to the root causes of problems, establish predictability, and drive precision in their process. Some deliverables and questions need to be addressed in each phase. Questions need to be satisfactorily answered and deliverables must be met before moving onto the next phase. There are checkpoints before each phase ends or what we call phase gate reviews. Here stakeholders and Six Sigma Black Belts assess the information available and discuss whether they can move to the next phase or not.

Define

The Define phase focuses on properly defining the problem from a business perspective. The project team is formed in this phase consisting of Black Belts, Green Belts, and in some cases Yellow Belts. The project team then gathers more information about the problem. Here they reach out to process stakeholders to further understand the scope of the project and their needs. Through this, they can identify which business functions are affected and will need to support it. The project sponsor and subject matter experts from involved functions are also determined.

Common tools used in this phase include:

- Project charter including project team, timeline, milestones, and goal statement.

- Process Map (VSM, SIPOC)

- Customer requirements (Voice of Customer, Critical quality attributes)

Measure

In the Measure phase, the project team examines how the process is currently performing based on the customer requirements and critical quality attributes identified in the Define phase. Process data is collected to quantify process performance. The type of data needed will depend on what’s available and what problem needs to be solved. There will be situations where the team needs to devise a way to extract data from the process. This is done through the help of the process subject matter experts. A thorough understanding of the process is crucial in this phase. Quality attributes such as process time, delivery speed, number of defects and other process quality indicators are collected.

If the process is not well-documented, the project team needs to flesh out each step of the current process. This often makes the Measure phase the longest and most tedious phase in the DMAIC process. At the end of this phase, the project team should have a more accurate representation of the current state process performance. This is how baseline performance or Sigma Baseline is established

Common tools used in this phase include:

- Data Collection Plan

- Sample Size Calculator

- Measurement System Analysis

- Process Capability Analysis

- Sigma Baseline Calculation

Analyze

The objective of the Analyze phase is to determine the root causes of the problem. This is done through both qualitative and quantitative approaches. Using the data that was collected in the Measure phase, the team validates the problem that was identified in the Define phase and finds its possible root causes. Problem validation is important because the team may have assumed the wrong problem at the onset. This results in formulating improvement recommendations that will not effectively solve the problem. The project leader needs to prove the existence of the problem through statistical and mathematical means. Quantifying the problem provides a solid basis of the claim and drives solutions that will be implemented on the next phase.

Various statistical control techniques are used in this phase. Some find this the most intimidating phase with all the math involved. This is why project teams would use statistical analysis software like Minitab and SPSS to make calculations much easier.

Common tools used in this phase include:

- Run charts

- Pareto Analysis

- 5 Whys

- Fishbone Diagram

- Time Analysis

- Histogram

Improve

The fourth phase of the DMAIC process is where solutions are created. A common pitfall Lean Six Sigma teams face is that they don’t thoroughly undergo the Analyze phase as they rush to formulate solutions instead. It’s important that before moving to the Improve phase the problem has been clearly identified and its root causes properly verified.

In the Improve phase, several solutions are formulated and each one needs to be assessed for viability. When a solution is selected, it undergoes pilot implementation and close monitoring to track and measure how effective the solution is. Data gathered during the pilot implementation is compared to the baseline performance data gathered during the Measure phase. This makes the comparison quantifiable and proves or disproves the effectiveness of the solution.

Once significant improvement is proven and target performance levels are met, the solution is formalized. Roll-out of the solution is planned along with accompanying training for the business units affected by the change.

Common tools used in this phase include:

- Design of Experiments

- Design for Six Sigma

- Failure Modes and Effects Analysis

- Simulation

- Impact Effort Matrix

- To-be Process Map

Control

The last phase of the DMAIC process is Control. In this phase, the solution is fully implemented and the to-be process is achieved. Throughout this phase, the new process performance is consistently measured and checked if within the acceptable range. A control plan is used for this purpose and guides the team in ensuring that the improvement plans take shape and the new performance levels become permanent.

There are instances when initial solution plans will need to be adjusted based on results experienced during implementation. This is perfectly fine. The important thing to do here is to also make sure process and training documentation are kept up to date.

The Control phase, and consequently, the Lean Six Sigma project ends when the project team determines that the new process is stable. This is usually characterized by consistently hitting the desired process performance levels. Another indicator is when the affected business unit no longer needs the guidance and support of the Lean Six Sigma project team to perform the new process.

Common tools used in this phase include:

- New Sigma Level calculation

- Control Charts

- Control Plan

- Audit plan

- Standard Operating Procedures

Phase Gate Reviews and DMAIC Deliverables

In Lean Six Sigma DMAIC process, we have what we call Phase Gate reviews. These are process checkpoints that determine if work in a phase has been successfully completed. Black Belts who are managing the project facilitate these reviews along with key stakeholders including the project team, senior management, and process owners.

Why We Need Phase Gate Reviews

Lean Six Sigma is a structured approach to problem solving. Key questions need to be adequately answered at each phase to ensure enough information is available for the team to move onto the next phase. Here are the reasons why phase gate reviews are necessary:

- Provides a formal way to assess if the correct questions have been answered and key phase deliverables are sufficient. This prevents rework and ensures the team has the right information to move forward to the next phase.

- Helps align the project team’s approach for the next phase based on the previous phase’s results.

- Enables the project team to assess for possible risks and issues that can be experienced on succeeding phases.

- Allows Black Belts to coach the project team to ensure work is done according to Lean Six Sigma standards.

DMAIC Deliverables

Here we define the key deliverables along with the questions that need to be answered for each Lean Six Sigma DMAIC phase.

Phase |

Key Questions |

Deliverables |

|

Define |

|

|

|

Measure |

|

|

|

Analyze |

|

|

|

Improve |

|

|

|

Control |

|

|

There are several tools used to accomplish the phase deliverables. Implementation can vary and will depend on the needs presented by the project.

DMAIC Process in Lean Six Sigma

DMAIC is at the heart of each Lean Six Sigma project. It is the framework that guides Lean Six Sigma teams to drive the best possible outcomes from their projects. In Lean Six Sigma, the DMAIC process is supercharged with Lean solutions and techniques to help identify process problems and surface its root causes accurately. Lean provides another lens for teams to examine processes that focus on waste elimination and flow optimization. Lean solutions help create improvement ideas that maximize the value experienced by the customer while maintaining cost-efficiency. You can use a variety of Lean techniques at each DMAIC phase. Following the DMAIC approach rigorously and maximizing both Six Sigma and Lean tools will ensure sustainable improvement is achieved on your Lean Six Sigma projects.

To see Agile DMAIC in action, check out our Basic and Advanced Agile DMAIC Template.