Andon

What is Andon?

Andon is a Japanese term meaning “light” or “lamp.” In Lean manufacturing, an andon refers to a tool that is used to inform and alarm workers of problems within their production process.

It is an integral part of applying Jidoka in the workplace. Jidoka means “automation with a human touch.” To implement Jidoka, teams must have the ability to spot an abnormal condition in the assembly line and stop production as needed.

Toyota has used andon cords to help workers quickly raise issues in the production line as they occurred. Pulling the cord initiated a signal sent to the supervisor to review the issue. The andon notification is displayed using a color-coded light system that indicates the current status at each workstation. The supervisor performs genchi genbutsu by going to the area of concern and investigating the problem.

Andon – Toyota Production System – Source: Toyota.co.uk

Types of Andon

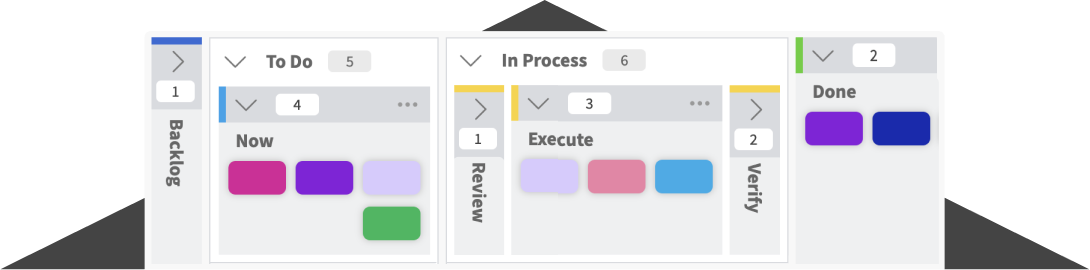

The andon used on production floors has evolved from basic cords and lights to complex boards. These boards provide a quick glance view of production status and easily identify the location of issues to be addressed.

Andons can be manually or automatically activated. It is manually activated when a production line worker engages an andon device like a cord or button.

An automatic andon is instantly activated when a process or machine encounters an inconsistency based on set criteria.

Benefits of Andon in the Workplace

Having a visual method to quickly identify issues allows for swift action and resolution. Its visual manner of presentation provides a clear picture of the overall production status.

The practice of using andon promotes transparency within teams and encourages issues to be identified rather than hidden for fear of judgment. It emphasizes the focus on resolving quality and safety issues over finger-pointing and blame.

It also allows companies to save money and time otherwise wasted because of defects and machine breakdowns.

We recommend that you occasionally review your processes. Do you have mechanisms in place to identify issues early on? If not, determine how you can make an andon that fits your team’s needs.