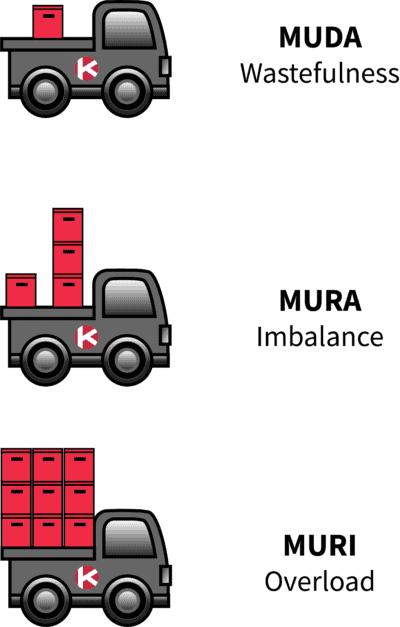

Stemming from the Toyota Production System, the 3M model – Muda, Mura, Muri – exposes the culprits to inefficient processes that plague business operations. But why do we need to tackle all three of them?

The goal of Lean is to deliver increased value to the customer by eliminating wasteful processes. When one talks about waste in this sense, often they refer to the seven wastes in manufacturing or Muda from the 3M model. Mura and Muri are often excluded from the picture but knowing these two is crucial as they are more likely to have caused Muda to appear in the first place. A good understanding of all three will surely help any business in streamlining its processes.

What is Muda, Mura and Muri?

Muda is the Japanese word for waste but we do not refer to it here as the pile of scrap materials that you see in a shop floor. Muda, in business process terms, refers to any activity that does not add value to the creation of the product or service for the customer. If an activity costs money, consumes time and resources, but adds no value to your finished product, then it is definitely Muda.

The seven wastes in Lean Manufacturing guide us in spotting Muda in our processes. Often called Mr. Tim Wood by some to remember them easily, these wastes are not only apparent in manufacturing but in service businesses as well. Let’s get to know what they are and explore some examples.

- Transport: Unnecessary transfer of products or materials from one location to another

- Inventory: All components, work in process, and finished product not being processed

- Motion: Excessive or unnecessary movement of a person or machine to perform the operation

- Waiting: Any act of waiting before performing the next step in the process

- Overproduction: Producing beyond what is expected

- Over Processing: Doing more than what is necessary to process a product or service

- Defects: Products that do not meet quality standards and result to rework

Mura is the Japanese word for unevenness or variation. In business process terms, these are inconsistencies in business operations; leading to fluctuations in production. Variations in production or processing can lead to employees being overworked due to peak periods in order to meet demand, then becoming idle when demand drops. Having uneven workloads can also lead to work in process inventory accumulation and waiting. When employees are overworked, there is a higher possibility for defects to come out of the pipeline. Looking closely, the presence of Mura leads to Muda.

Muri is the Japanese word for overburden. In business process terms, this is referred to as putting too much stress and strain on people and machines. We can see these in employees working overtime to meet targets, and machines operating more than 100% of their capacity, to name a few. These instances often stem from the presence of Mura. Due to the variation in the pace of work, employees and machines are sometimes subject to exert effort that is beyond their capacity. Muri then also leads to Muda. Overburdening people and machines could lead to defects, and downtime which can lead to excess work in process inventory and waiting.

Looking at it collectively

When examining business processes for inefficiencies, it is important to take into consideration the presence of all three – Muda, Mura, and Muri. They are all interrelated and are all considered wastes. One does not look for Muda alone and hope to solve a process problem completely. It would be more likely that you need to sort out Mura and Muri first to eliminate Muda. This will ensure that the risk of Muda returning to your process is mitigated.

Let’s take some examples to understand how these three are interrelated.

Suppose a company’s manufacturing department is rated based on the units they produce monthly. This leads them to constantly increase their output month-on-month to depict an uplift in their production. By the last week of the month, the department realizes they are still short of their target units, and so they ramp up production before the month closes off. This sudden peak in production (Mura) leads to the employees and machines operating more than their full capacity (Muri). Not necessarily backed by customer demand data, the increase in units produced also leads to overproduction (Muda).

Now let’s take a look at a non-manufacturing setup. Let’s say a software development team has 4 developers and 2 quality analysts. All developers are able to transition their coded features for testing at the same time. With this, the capacity of the developers is higher than the capacity of the quality analysts (Mura), since some features will have to wait before they get tested (Muda). This leads to work in progress items accumulating within the process (Muda). This can also urge the developers to pace their work (Mura) so that the next step isn’t overburdened. Trying not to be a bottleneck and to ensure features get out on time, the quality analysts then pursue overtime to work on all their pending tasks (Muri).

You see, all these three are most likely in play when you examine your processes for inefficiencies. It is by examining your process as a whole and taking into account the 3M model will you be able to conduct an effective diagnostic of your operations.

Fighting the 3Ms

After you’ve identified the Muda, Mura, and Muri in your processes, it’s time to tackle them head-on. There are a variety of Lean tools that you can explore to manage the presence of 3Ms in your processes.

It is recommended that an understanding of the entire process flow be achieved first before introducing any resolution. For this, conducting Value Stream Mapping is ideal. Having a Value Stream Map will help you identify where in the process do these wastes occur and why they occur.

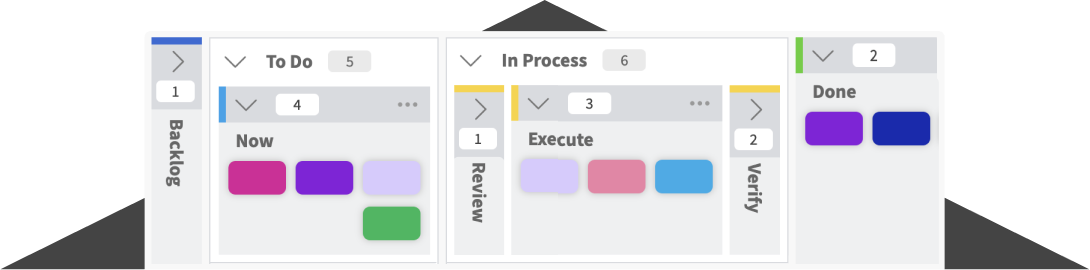

Knowing what problems you need to tackle, and depending on the need, you can then proceed with applying lean tools such as 5S, Just-In-Time (JIT), Kanban and Heijunka.

5S will help you ensure a methodical and systematic approach to organizing the workplace is established – lessening the possibilities for wastes to occur. Adapting the JIT principle through the use of Kanban and Heijunka will help you ensure a steady pace of work which lessens waiting, overburdening, and inventory in your processes to name a few.

We at Kanban Zone encourage you to take a closer look at your processes and scan them for the presence of Muda, Mura, and Muri. You can explore a variety of lean tools that can help you to expose and manage them – helping you create efficient processes for your business.