Over the past years, the manufacturing industry has been looking for different alternatives aiming at working in a more practical and efficient way while delivering high-quality products. Among the many existing manufacturing segments, the machining segment has been using different technologies in order to accomplish this goal. One such technology is known as the CNC (Computer Numerical Control) technology, which has found many applications in different machining processes like drilling, turning, milling, grinding, etc…

What is Computer Numerical Control (CNC) technology?

In a brief view, the CNC technology refers to the automated command of machine tools which are controlled by a computer according to set input commands (or instructions) in the form of a sequential program, called CNC program. Despite presenting increased productivity and other advantages over conventional (non-computerized) machining, some drawbacks of CNC technology are still noted as for example high costs and setup time.

The Kanban method has its origins in the manufacturing segment and more recently is being used as a powerful way to represent a process in a Kanban board in order to better understand and improve the process. What if the Kanban method could be used for the CNC manufacturing process?

This article, it is proposed a way of using the Kanban method to help you in the CNC manufacturing process of machined parts. Regular CNC machine maintenance is essential to prevent breakdowns and ensure consistent production quality.

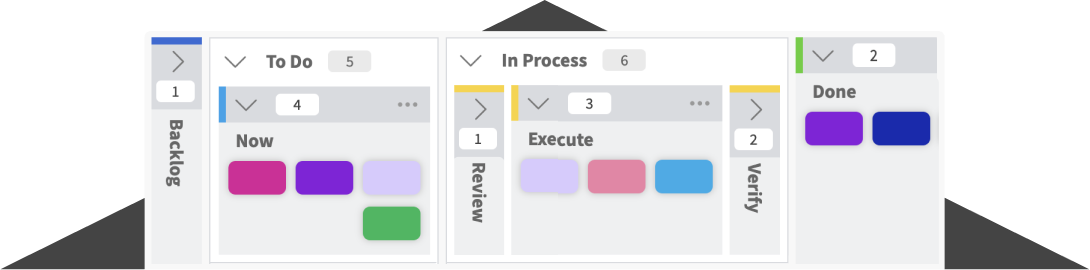

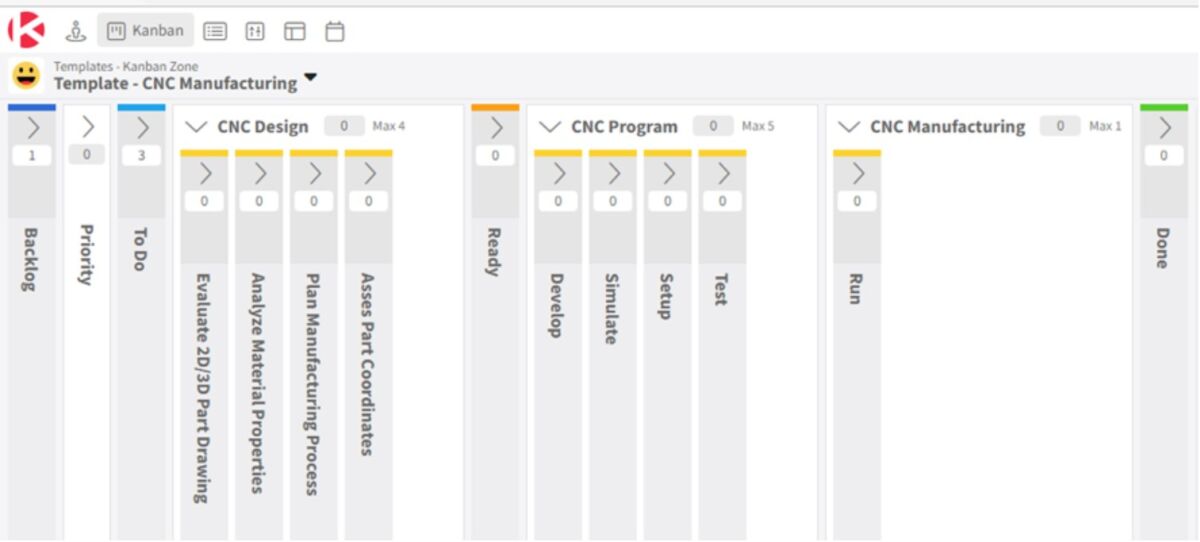

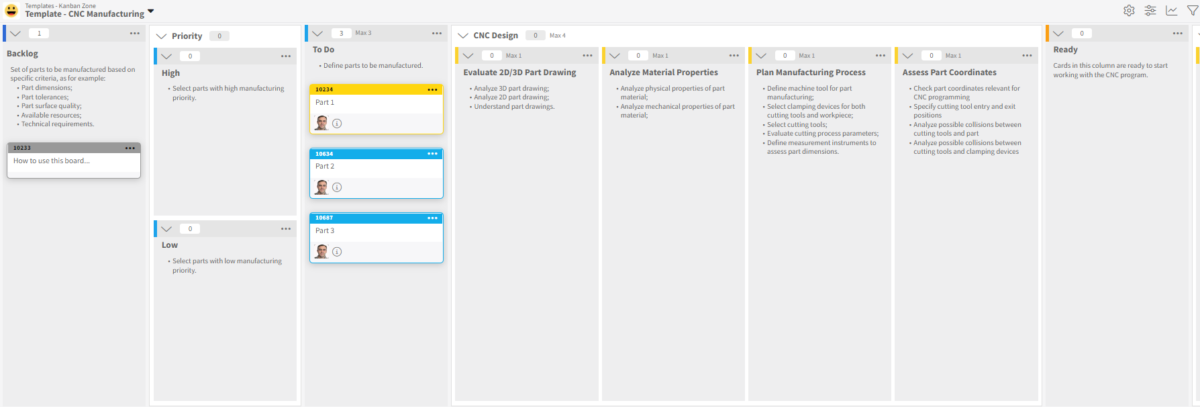

Succinctly, the CNC manufacturing process aiming at producing machined components or parts in the industry can be represented as shown in the Kanban board below.

The column names of the board show the required process steps in order to get the needed component through an efficient process flow. Besides the typical columns “Backlog”, “To-Do” and “Done”, this Kanban board is divided into three main process stages:

- CNC Design

- CNC Program

- CNC Manufacturing

These stages are critical to correctly producing the desired components. Each of these three process stages are in turn divided into other additional process steps that are addressed in more details in this article.

Stage 1: CNC Design

In the “Backlog” column, you can start specifying the set of parts to be manufactured based on specific criteria, as for example, part dimensions, tolerances and surface quality as well as the available resources for manufacturing. The manufacturing priority (high or low) among the parts listed in the “Backlog” column can now be defined in the column “Priority” of the Kanban board. For each part, a specific card can be created in this Kanban board representing a task that needs to be accomplished.

After having defined the parts manufacturing priority, their associated cards can proceed to the “To-Do” column of the board. Next, the “CNC Design” stage of the board takes place by taking into consideration important process steps, as for example, 2D/3D part drawing evaluation, material properties analysis, manufacturing process planning and the assessment of part coordinates. All these process steps are represented as particular columns inside the “CNC Design” stage.

The column “Evaluate 2D/3D Part Drawing” refers to the importance of becoming familiar with the part specifications. This can be achieved by firstly receiving the part drawing that must be analyzed and understood.

Next, in the process step “Analyze Material Properties” it is important to get reliable information regarding the part material as it directly influences machining parameters, the type of cutting tool as well as the CNC machine tool used in the manufacturing process. Both physical and mechanical properties of the part material must be known in this process step.

By gathering all the information achieved in the previous process steps of the “CNC Design” stage, it is possible now to advance to the process step “Plan Manufacturing Process”. Here, many technical aspects concerning the way in which the machining process will be carried out must be considered, as for example:

- the definition of the CNC machine tool;

- definition of the machining operations and their logical sequence;

- selection of cutting tools and workpiece clamping devices;

- evaluation of cutting process parameters; and

- definition of measurement instruments to assess the part dimensions.

Once you know the way of fixing the part and the machining process, thus in the last process step of the “CNC Design” stage (“Assess Part Coordinates”) you can check part coordinates that will be relevant in the CNC programming. The cutting tools entry and exit positions must be predicted and possible collisions between cutting tools and the part need to be analyzed carefully.

Now, the card associated with the part to be manufactured proceeds to the column “Ready” which represents a buffer process step. Cards in this column are ready to be pulled to the “CNC Program” stage of the Kanban board.

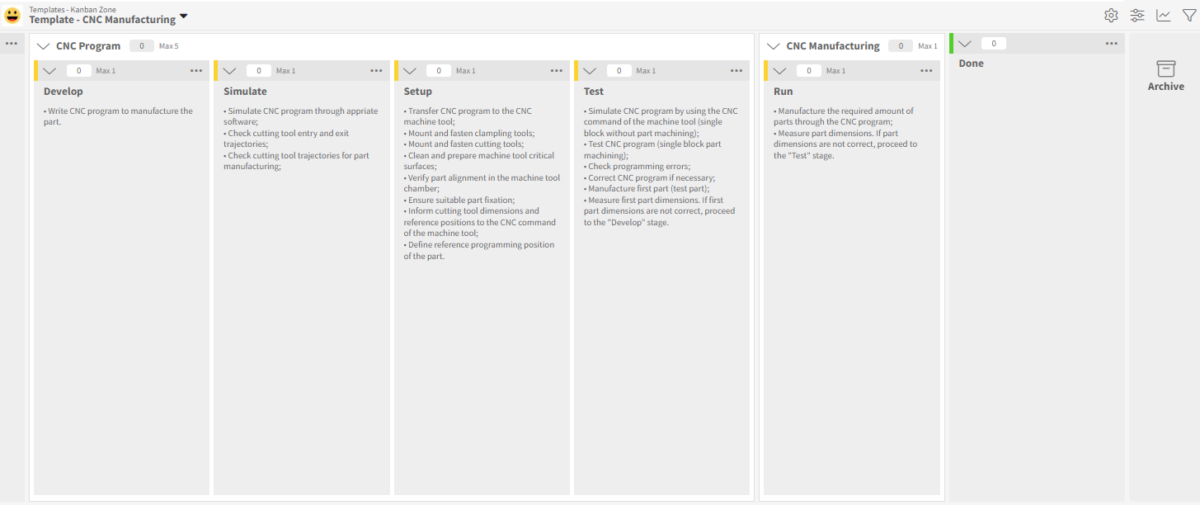

Stage 2: CNC Program

The “CNC Program” stage is composed of four process steps (namely, “Develop”, “Simulate”, “Setup” and “Test”) which are critical in achieving a consistent CNC program to manufacture the part.

In the “Develop” process step, the CNC program needs to be written by the team in an appropriate code (also known as “G”-code) that the command of the CNC machine tool can understand in order to manufacture the part.

Next, the developed CNC program must be simulated aiming at avoiding errors and confirming its functionality. This is carried out in the process step “Simulate” by using appropriate software which helps checking if cutting tool trajectories are suitable for part manufacturing.

After finishing the CNC program simulation, you can proceed to the process step “Setup”. Firstly, the CNC program needs to be transferred to the CNC command of the machine tool. This can be done by using different media, for example, cable, storage devices, and so on. Important procedures in this process step are related to the definition of the cutting tool dimensions and reference positions to the CNC command. Additionally, the preparation of the CNC machine tool for manufacturing the part is also important and it involves mounting and fastening both clamping and cutting tools, cleaning of critical surfaces, verifying part alignment in the machine tool chamber and proper part fixation.

Now that you have developed, simulated and set up the CNC program, it is time to advance to the process step “Test” which stands for assessing the CNC program in the CNC command of the machine tool and making corrections where necessary. In this process step, you can machine the first part by using the CNC program. This first part is actually a test part (or pilot part) and is used to verify and validate the CNC program and the previous procedures. If the part dimensions are correct you are allowed to proceed to the next process stage (CNC Manufacturing), otherwise, go back to the “Develop” process step and make the required adjustments.

Stage 3: CNC Manufacturing

In the last process stage (CNC Manufacturing) it is time to manufacture the required amount of parts through the CNC program and the CNC machine tool. In case the part dimensions are not correct, you can return to the “Test” process step and verify what went wrong, thus making the necessary revisions and going forward with CNC manufacturing of parts. An expanded view of the previous Kanban board is shown below.

Under each column of the board, explicit agreements are defined which help you to decide when to pull the cards from one specific column to the next process column in the Kanban board. The different colors of the cards help identify distinct types of components (either cylindrical or prismatic parts) that can be manufactured and have also been added to assist you when beginning to use this Kanban board.

Besides the possibility of better visualizing your CNC manufacturing process, the CNC manufacturing process Kanban board template can help you in getting important metrics related to your process, as for example, cycle time, lead time and flow efficiency, thus assisting you in the journey of constant process improvement.

Learn to Work Smarter, Not Harder!

Get our top articles weekly.

Table Of Contents

Discover many more posts…